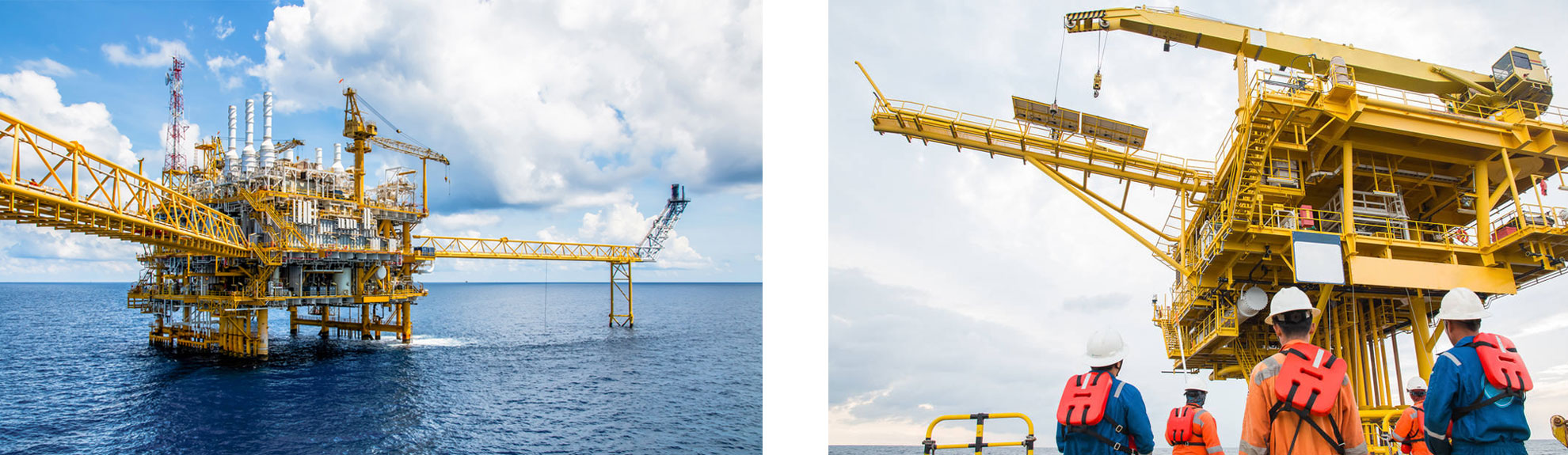

Offshore platform for offshore drilling, oil extraction, CSCL, observation, navigation, construction and other activities

to provide production and living facilities of structures. Offshore environments are rugged areas that require

specialized products to handle the aquatic environment and unique service conditions ranging from simple water and

salt intrusion to special corrosion and pressure requirements.

Follow the development of offshore oil field exploitation, the amount of offshore platform need valve also gradually

increasing. Offshore platform need shut off ball valve, check valve, multi-channel valve. YDF Valve own special

performance testing lab and advanced equipment. YDF Valve professional project team will provide solution to meet

the strigent requirement of the offshore industry.

The modern crude oil refinery is designed to convert basic raw crude oil into various useful products through a series

of separation and chemical processes. Refineries consist of many different processes such as distillation units,

fractioning towers, alkylation units, catalytic crackers, reformers and coking units. Fire is a constant and significant

risk in oil refineries –one that demands effective fire protection system. By nature, many refining applications

characterized by extreme temperatures, erosion, corrosion, and high pressure drops. With strict

environmental requirements, process equipment must also restrict fugitive emissions to acceptable limits.

Valves in the future will cooperate with industrial automation, promote the overall level of valve equipment, development

of multi-function, high efficiency, low consumption of oil refining equipment valve. Our commitment to the refining

industry is stronger than ever as we continue our tradition of supporting the needs of our customers throughout

the world with the ability and knowledge to provide Specialty Valves and Control Systems service with an emphasis

on safety, quality and high efficiency.

As increased global demand in hydrocarbon depletes once established reservoirs, the complexity, cost, and difficulties of finding and extracting new reservoirs have been steadily increasing. As companies face longer rig times, dangerous environments and increasingly the need to navigate through complicated networks of governance and environmental compliances YDF will keep expanding its abilities to provide viable solutions to the challenges of modern day oil and gas production.

-

Upstream

Upstream is the exploration and refining of crude oil both on and off shore. YDF continuously improves its technical capabilities and global sales network to offer customers valve solutions that control cost.

-

Midstream

Midstream is the implementation of safe and efficient transportation of oil & gas products between production and storage areas to the processing plants and consumers. YDF has abundant experience in pipeline and transmission valves.

-

Downstream

Downstream process involves refineries and processing plants of oil & gas products. These operation plants require a large variety of different valves which are a necessity due to the various final products. As the largest valve producer in China, YDF valve has a large offering of different valves enabling clients to minimize cost by reducing logistic complexity and assist in compliance to various environmental and governmental criteria.

Increased shipping demands brings shipbuilders plenty of opportunities and challenges. YDF’s customized marine valve solutions can help shipbuilders and ship owners to select suitable valves in order to save cost and reduce risks. YDF has become the preferred choice of valve supplier in marine industry because of its reliable quality, complete product categories, marine accreditations and global service network.

YDF produces standardized valve products which reduce maintenance requirements of components and eventually help ship owners reduce their maintenance costs. Universality of YDF products helps to save space and weight which is very important for submarines and ships with very limited space.

In chemical industry there are various categories, products and complex technologies. Miscellaneous pollutants in large quantities and high toxicity are discharged during the production. Therefore, it’s vital for the chemical industry to achieve sustainable development and reduce harmful emissions.

The modern day chemical industry has committed itself to reducing emissions and improving the safety & environmental protection of factories. They also encounter severe government management requirements which vary for different countries and markets. YDF offers excellent products to meet requirements in chemical industry. Our valves own all applicable international accreditations and meet the most stringent environmental requirements, including Europe TA Luft, ISO 15848 and SHELL 77/312 FE standard. YDF’s global sales network and powerful manufacturing capability combined with abundant experience and technical knowledge helps customers to realize continuous technical innovation in chemical industry.

Valves are indispensable and important equipment for safe operation, maintenance, transformation and development of gas transmission and distribution and storage systems.

In the process of gas production, purification, storage, transportation and application of urban gas, valves must be installed whenever cutting off, diversion, diversion, check, pressure relief, pressure stabilization and bypass are needed. Valves are widely used. According to authoritative statistics of petrochemical industry, the proportion of valves in the total investment of engineering projects reaches 8%. Because natural gas is flammable and explosive, it is particularly important to ensure the safety and reliability of valves in operation.

FPSO, (Floating Production Storage and Offloading),which preliminary processes and stores of crude oil, is known as "offshore oil factory", and is the main mode of production in offshore oil and gas industry. FPSO, as a part of offshore oil and gas development system, generally consists of a complete production system with underwater oil production equipment and Shuttle Tanker. It is a high-tech product in ocean engineering ships. At the same time, it also has the characteristics of high investment, high risk and high return on marine engineering.

There are many challenges in the construction, operation and maintenance of FPSO. Corrosion, high pressure, sea water, deep sea and other working conditions require special design and manufacture of valves for FPSO systems, using corrosion resistant materials, seals and external coating. YDF provides ball valves, butterfly valves, gate valves, globe valves and check valves for FPSO systems. It has high stability, reliability and safety.

Compared with gaseous natural gas, LNG has the characteristics of more convenient carriage and storage. As an efficient and storage clean energy, LNG has shown broad prospects in all aspects of the industrial chain. With the rapid development of LNG industry, the demand for cryogenic valves is increasing day by day. Because LNG is flammable, explosive and ultra-low temperature, and LNG plant is usually located in the seaside salt spray environment, it puts forward higher requirements for the selection and design of cryogenic valves.

Oil pipeline is not only an energy supply line, but also a lifeline related to economic development and people's livelihood security. Valve is one of the main equipment in pipeline industry. It plays a key role in safe and reliable operation in pipeline transportation. General speaking ,although crude oil and natural gas are processed, still contains sulphur, rust and metal particles, and it requires zero-grade sealing. The harsh environment and the importance of energy supply lines in actual use put forward strict technical requirements for pipeline ball valves.

Storage tank is an important infrastructure of loading and unloading-storage system, as well as an important link in crude oil, refining, chemical and other industries. The main products stored in petrochemical industry are liquid or gaseous raw materials, products and intermediate products. The potential risk of storage is high. Therefore, the industry requires high quality, performance and quality of storage tanks. YDF can provide professional and all-round solutions for the above devices.

Everywhere in the world is making every effort to meet the growing demand for electricity worldwide. The power industry has been looking for new ways to develop precious energy resources more quickly, safely and efficiently, while minimizing the impact on the environment. In the fields of coal power generation, natural gas power generation, nuclear power generation and other renewable energy sources, YDF helps customers solve their challenges. With technical and professional engineering experience, service solutions and global capabilities, we provide customized end-to-end solutions for customers at all stages of power generation projects. From traditional power plants to nuclear and renewable power plants, YDF helps customers with different power ranges to reduce downtime, optimize energy efficiency and create a safer working environment.

Air separation units are widely used in various industries, such as oil and gas, chemistry, paper making, metallurgy and so on. Air separation unit separates air into various main components, such as oxygen, nitrogen, argon and other inert gases. The main products of air separation unit are oxygen and nitrogen.

With the rapid development of metallurgy, chemical industry and coal chemical industry, new requirements have been put forward for the technical development of supporting equipment while requiring the development of air separation equipment in a larger scale. With the continuous large-scale domestic air separation equipment, new technical requirements for matching valves are constantly put forward.

YDF can provide a complete set of valve solutions for the air separation industry.