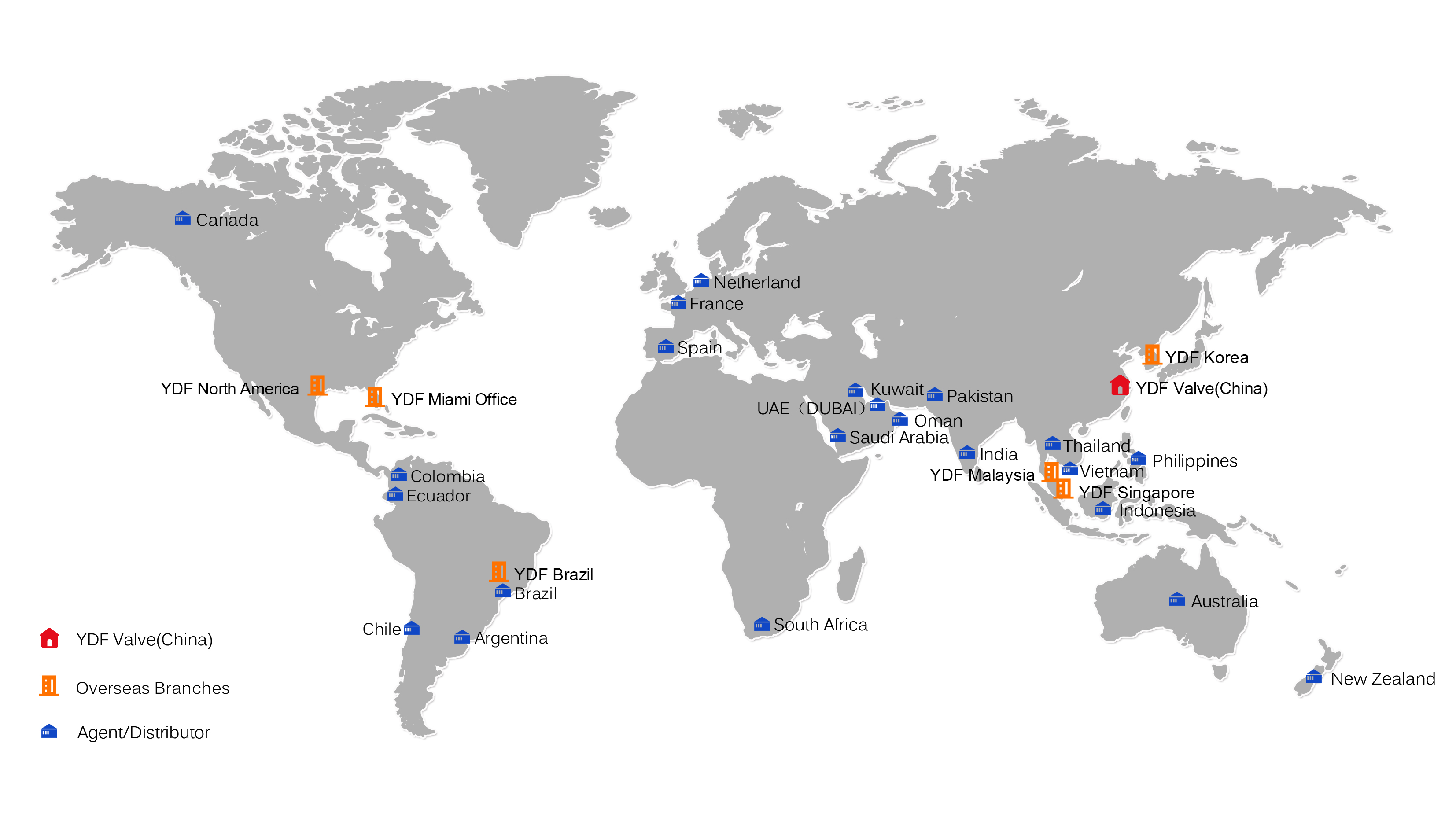

YDF Valves has four assembly plant, two foundry, three operation and sales service centers in China, and additional overseas branches in the U.S.A., Brazil, Singapore, South Korea, Malaysia and Russia. It relies on the global agent and worldwide after-sales service outlets, such as UAE,Spain,Thailand,Australia,South Africa,Canada and so on. Customer always comes first. YDF Valves together with its energetic and passionate global team, will take on challenges in the future.

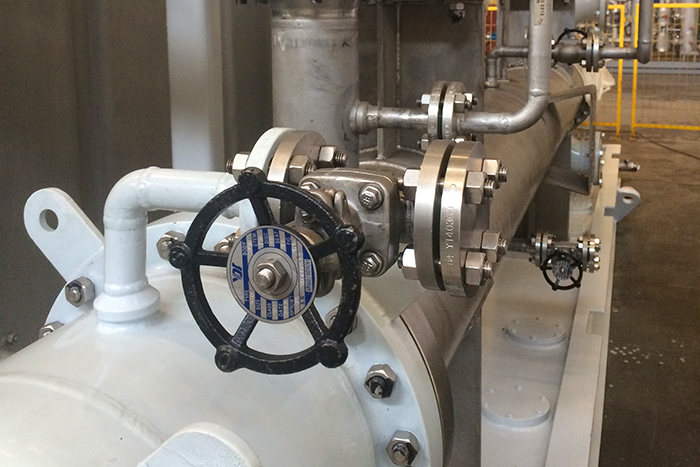

Proper sizing, selection, and maintenance of valves and actuators, is crucial to process control loop operation. As an added value to our clients, YDF valve meet with customers to provide training and guidance on important issues such as valve technology, proper maintenance, operation, preservation, and handling. In addition, we regularly organize technical & quality training to enhance the exchange between YDF and our clients. Our certified instructors will share their knowledge and experience of valves and actuators through lecture and hands on project site.

YDF Valves has an international reputation for the quality of training it provides customers, installers and maintainers of fluid control systems. Our aim is to ensure that you achieve the maximum benefit both efficiently and safely.

YDF Valves own professional after-sale service team around world for valve maintenance & consultation, well equipped and high positioned. Good teamwork guarantee customers timely, superior and professional services, which include:

·Providing professional 24-hour hotline and online service ,such as technical exchanges, solutions and support

·Preparation of spare parts for customer

·Professional customer site service

·Inspection of goods, on-site commissioning and guidance at the initial stage of operation

·Customized maintenance proposals

·Systematically analysing potential causes and Problem

·Regular valve maintenance and inspection service

·Providing technical guidance and training

When it comes to the design and evaluation of instrumentation and control systems installed for safety purposes, no easy answers exist. A methodical, team-oriented life-cycle approach is required. YDF Valves provide systematic safety guidelines for valve selection,storage ,installation,commissioning, operations, maintenance and replacement.

Installation and commissioning. This step ensures the system is installed per the design and performs per the safety requirements specification. Before a system is shipped from the factory, it must be thoroughly tested for proper operation. If any changes are required, they should be made at the factory, not at the installation site.

Operations and maintenance. Every system requires periodic maintenance to function properly. Not all faults are self-revealing, so every safety system must be periodically tested to make sure it will respond properly to an actual demand. The frequency of inspection and testing should have been determined earlier in the life cycle. All testing must be documented.

-

Product Summary

YDF’s main product lines include Ball, Gate, Globe, Check, Butterfly and Power Station valves, size range of 1/2 inch up to 60 inch , pressure rating of 150LB~2500LB...Download -

Gate Globe & Check Valve

YDF Gate, Globe and Check Valves are manufactured in accordance with API, ASME B16.34, BS 1873, BS 1868, AP I594 specification and tested to API,and...Download -

Floating Ball Valve

YDF Floating Ball Valves are manufactured in accordance with ISO17292, BS5351, ASME B16.34, API etc. Fire safe design certification by: API 6FA, API .Can meet...Download -

Trunnion Mounted Ball Valve

YDF Trunnion Mounted Ball Valves are manufactured in accordance with API 6D, ASME B16.34, certified to API sixth edition, API 6FA third edition fire safe tested design...Download -

Butterfly Valve

YDF Butterfly Valves are manufactured in accordance with API, ASME B16.34. Available to offer fire sate tested design, which is certified to API .Size range is from...Download -

Cryogenic Valve

YDF Cryogenic Valves are manufactured in accordance with API, ASME B16.34, BS 6364 , ASME B16.10.The valve size range is from 1/2 inch to 36 inch, all pressure...Download -

API 6D

YDF API 6D Valves are manufactured in accordance with API 6D, ASME B16.34. And the size range is from 2 inch up to 48 inch, pressure rating is from 150LB to 2500LB.To ensure...Download -

Forged Steel Gate Globe & Check Valve

YDF Forged Steel Gate, Globe and Check Valves are manufactured in accordance with API, ISO 15761 and ASME B16.34 and tested to API .And this series valves...Download