On March 13, YDF Valve passed the acceptance of the intelligent manufacturing phase I project - intelligent monitoring system of valve pressure test, becoming the first batch of companies in the region who passed acceptance.

In order to implement the strategy of intellectual change and digital transformation, accelerate the pace of company transformation and upgrading. YDF Valve cooperated with Yancheng Mobile, invested in the construction of valve test pressure monitoring systematic project to create an integrated platform for production test pressure monitoring in response to the challenge of digital transformation of key valve test pressure processes. The goal of the valve pressure test monitoring system project is to realize the standardization of valve pressure test operation, the immediacy and completeness of the data recording and reporting of the pressure test process, and to realize the transparency of the state of the equipment and standardization of the production operation through the high degree of integration of man, machine, law and measurement, so as to truly open the barriers of man-machine cooperation and improve the level of production control.

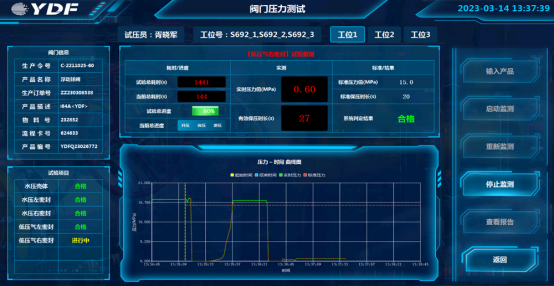

The valve pressure test monitoring system has brought significant changes to the valve pressure test work. Operators test pressure by scanning the product code to obtain the product "test pressure standard, test pressure, pressure holding time" and other data to ensure that the test pressure project in full accordance with the standard implementation, standardization of the test pressure process. The management can sit in the office and remotely view the real-time pressure process data of the on-site equipment, and clearly understand the relevant data of the staff pressure test process; each pressure test product can generate a monitoring report, record the monitoring process data, and automatically judge the monitoring results according to the process standards and the actual value, so that the whole pressure test process can be traced back.

Subsequently, based on the YDF ball valve workshop, the two sides will continue to carry out the second phase of the intelligent manufacturing project, to build an intelligent workshop, a 5G fully connected factory, to build an intelligent management platform for production and operation, to realize the multi-directional and comprehensive management of the enterprise's production and operation, to continue to empower the enterprise's production and manufacturing process, to accelerate the pace of the intelligent construction of the company, and to further to reduce cost and increase efficiency, and to reduce the labor intensity of the employees.